Professional Glass Processing Machines Manufacturer & Complete Glass

Solutions - Glass Washing Machine, Edging Machine etc.

Professional Glass Processing Machines Manufacturer & Complete Glass

Solutions - Glass Washing Machine, Edging Machine etc.

Product Details:

Payment & Shipping Terms:

|

| Product Name: | Appliance Glass Double Edging Machine Line For Refrigerator Glass Shelf , Bevel 45° Arris | Application: | Appliance Glass Deep Processing Industry |

|---|---|---|---|

| Glass Maximum Size: | 1300 Mm | Glass Minimum Size: | 120×120 Mm |

| Glass Thickness: | 0.5-6 Mm | Speed: | 3-8 M/min |

| Standard: | CE | Motor/Spindle: | 3+3 |

| High Light: | grinding and polishing machine,glass polishing machine |

||

Bevel 45 Arris Glass Double Edging Machine Line For Refrigerator Glass Shelf

Specifications:

Model | YEC6M1300 | YEC6M1600 | YEC6M2000 |

Max. Width of Glass | 1300mm | 1600 mm | 2000 mm |

Min. Size of Glass | 120*120 mm | 120*120 mm | 120*120 mm |

Table Height | 900-950 mm | 900-950 mm | 900-950 mm |

Glass Thickness | 0.5-6 mm | 0.5-6 mm | 0.5-6 mm |

Speed | 3-8m/min | 3-8 m/min | 3-8 m/min |

Parallelism Error | ± 0.1mm/m | ± 0.1 mm/m | ± 0.1 mm/m |

Diagonal Error | ± 0.3 mm/m | ± 0.3 mm/m | ± 0.3 mm/m |

Chamfer Safety Corner Error | ± 0.3 mm/m | ± 0.3 mm/m | ± 0.3 mm/m |

Total Power | 23kw | 23kw | 23kw |

Floor Space | 3650*3070*1930mm | 3650*3370*1930mm | 3650*3770*1930mm |

Weight | 5500kg | 5800kg | 6800kg |

Applications:

The Appliance Glass Double Edging Machine Line For Refrigerator Glass Shelf , Bevel 45° Arris is mainly used in the appliance flat glass straight line grinding and chamfer safety corner, such as refrigerator glass shelf etc. If it is used in the glass of 45° beveling of upper and lower arries of the straight-line, and the safety corner cutting.

Description:

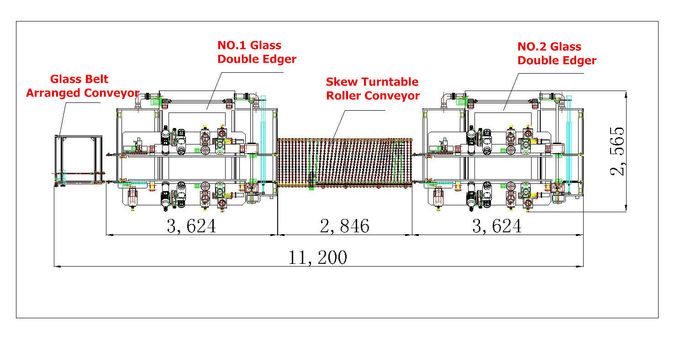

This Appliance Glass Double Edging Machine Line For Refrigerator Glass Shelf , Bevel 45° is mainly

composed of 1 set Glass Belt Arranged Conveyor, NO.1 Glass Double Edger, equipped with safety corner

chamfering, 1 set Skew Turntable Roller Conveyor and 1 set NO.2 Glass Double Edger.

The glass is sent to the NO.1 edging machine by automatic glass arrange machine, and make the straight corner cutting, processing first two straight line sides of the glass, then be sent into skew turning table, after the glass turning 90° by skew rollers, it come into NO.2 glass edging machine for processing the other two sides of the glass. Eventually the four sides of the glass including the safety corner chamfering processed one time, then into next process.

1. Solid structure,accurate and smooth drive system, advanced control system and powerful processing

capability.

2. PLC touch screen control, variable frequency speed control, right angle positioning correction

configuration to guarantee the parallism and diagonal precision when grinding flat glass.

3. The main transmission adopts variable-frequency motors.

Competitive Advantage:

1. Main transmission shaft is placed on the upper of machine, which extends main shaft life and easy to

replace synchronous belt.

2. The design of catch pawl ensures the high precision of glass diagonal.

3. Unique design of grinding head that improves the running accuracy and impact resistance of the

grinding head and prolongs the service life of the motor.

4. The design of three-point lifting pillar ensures perfect straightness.

5. The upper design of down chamfering motor ensures the completeness of sliding table, and keeps

machine structure more stable.

6. Automatic lubricating system extends equipment life.

7. High effienciency.

Technical Parameters:

Glass Belt Arranged Conveyor:

It is mainly used to solve the problem of glass spacing inconsistent, which cased by artificial works, it’ll largely affect the production efficiency, the corner chamfering device will not work and cause downtime,if the glass spacing is too small.

Configuration:

Components | Origin/Material |

Bearing | China |

Timing Belt | Bailey, Italy |

Gear Reducer | Wanshin, Taiwan |

Rack | Industrial Aluminum Profile |

NO.1/NO.2 Glass Double Edger:

It adapts PLC touch screen control, and the transfer speed is controlled by programmable controller. When you need to adjust the speed, you just modify the parameter by touch screen.

Technical Parameters:

12 KW (NO.2 Edging Machine)

Main Function:

Appliance Glass Double Edging Machine Line For Refrigerator Glass Shelf , Bevel 45° Arris